In this post, we’ll go over the basics of how to read engineering drawing symbols.

How to Read an Engineering Drawing Symbol

Engineering drawings are simple to pick up and use – once you understand how to read them. Unlike a model, engineering drawings offer more specific detail and requirements, such as:- Dimensions

- Tolerances

- Finish

- Geometry

- Hardware

- Material type

- Finish

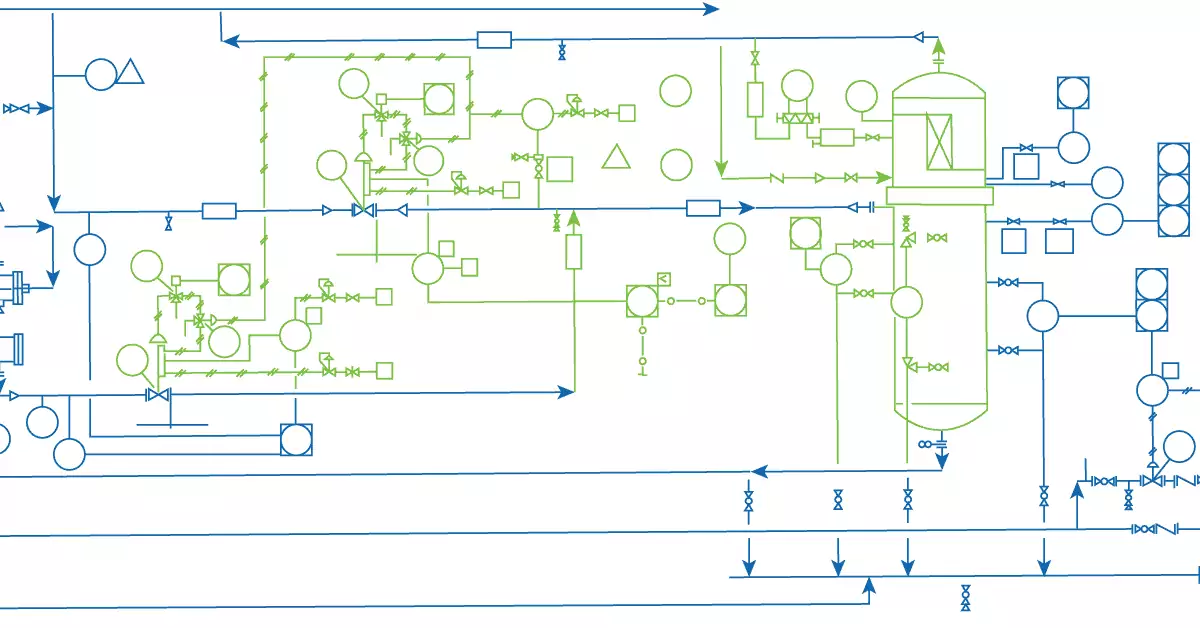

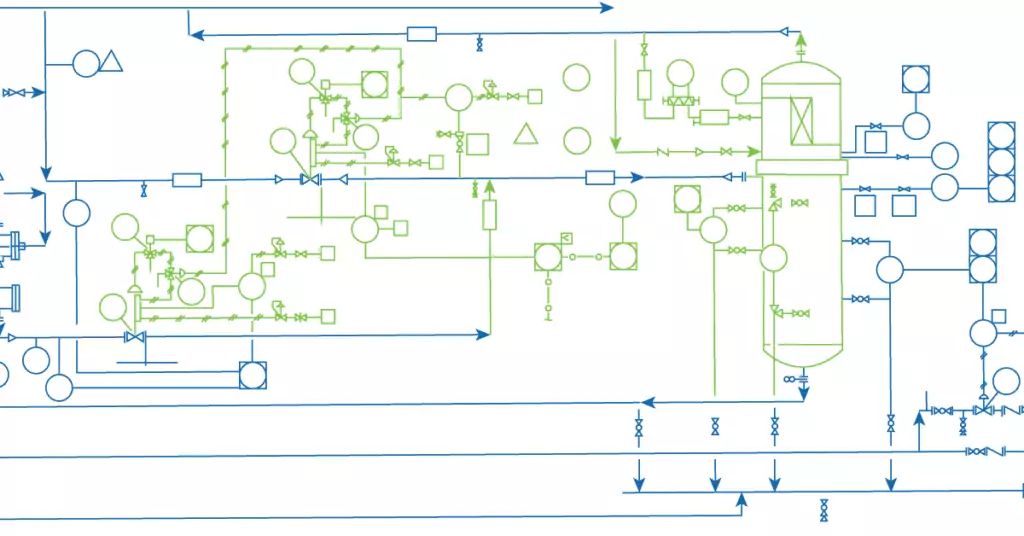

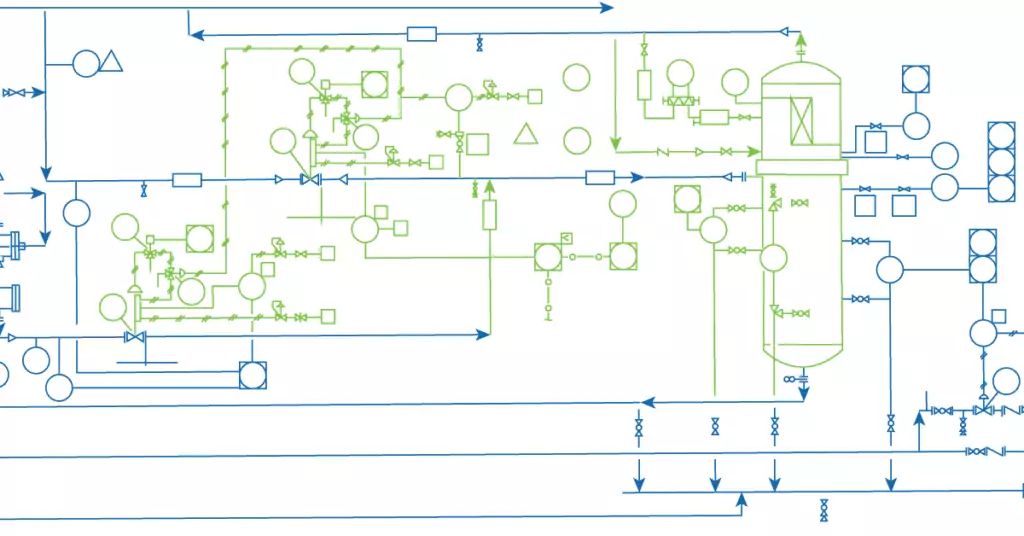

P&ID Engineering Drawings

P&ID engineering drawings differ from the typical mechanical variant; they include:- Mechanical equipment

- Control instrumentation and designation

- Computer-controlled systems

- Standardized components

- Process piping sizes and identification

- Pipe classes and piping line numbers

- Flow direction

- Interconnection references

- Permanent start-up, finish and bypass lines

- Pipelines and flow lines

- Blinds and spectacle blinds

- Insulation and heat tracing

PFDs of a Single Unit Process

PFDs differ from P&IDs, showing a more general overview of a system. PFDs of a single unit process include:- Process piping

- Major equipment items

- Major bypass

- Operational data

- Process stream name

Engineering Drawing Abbreviations and Symbols

To read an ED, you must first become familiar with the various symbols, abbreviations, and diagram basics. Once you familiarise yourself with these features, you’ll be able to trace the lines in a system to understand specific components and the overall function in the case of PFDs and P&IDs or understand the manufacture and assembly of a product in the context of mechanical engineering.PFD Equipment Symbols

PFDs use specific shapes to represent different equipment, valves, instruments, and piping flow in a system. They are a standard set of symbols used for the identification of measurements and functionality within the process. To provide detail about the components, a 5 letter system is used:- (Letter 1) L1 – Measured value

- L2 – Modifier

- L3 Readout/passive function

- L4 Output/active function

- L5 Modifier

Components of an Engineering Drawing

Several features describe a component, such as lines, views, and title-blocks.Types of Line

Lines in an ED show both visible and hidden edges of a part, centerlines, etc. – meaning not every line is equal.Continuous Line

A continuous line (also referred to as a drawing line) represents an object’s physical boundary. In simple terms, these lines draw out the object. The line thickness can vary, with the outer contours represented by thicker lines and the inner contours by thinner lines.Dashed Lines

Dashed lines (also referred to as hidden lines) show something that would otherwise not be seen on the drawing. These are seen in instances such as showing an internal step in a turned part without the need for a section or cut-out view.Dash-Dot lines

Dash-dot lines are used as center lines to indicate the center lines of a hole or show a part’s symmetric properties. This can help reduce the number of dimensions and annotations on a drawing to prevent over detailing.Extension Lines

Extension lines (two vertical lines joined by a double-headed arrow) annotate what is being measured. The measurement can sit on top or inside the lines.Break Lines

Break lines (continual lines with intermittent zig-zags) indicate that a view has been broken. They condense the data into a smaller amount of space, for example, in a symmetric or continuous uniform component.Cut-out Lines

Cut-out lines (two arrows joined by a dash-dot line) are used to show the cutting plane and trajectory of the cut out in a cut-out view.Views

There are several common views in mechanical engineering and manufacturing drawings. Each view should serve a purpose and be used to communicate vital details. As with dimensioning, as few as possible views should be used; only necessary items should be shown. A view should only be included if it contributes to the overall understanding of the design.Isometric View

An isometric view shows a 3-D view of the part. In this type of view, vertical lines – as seen on 2-D drawings – remain vertical, and parallel lines are shown at a 30-degree angle to the horizontal. Vertical and parallel lines remain true in length, making dimensions transferable when scaling a drawing. Angled lines do not indicate dimensions. An isometric view can often be confused with a perspective view. However, a perspective view represents an object as it seems to the eye; isometric views stay true to the dimensions instead of creating an optical illusion.Orthographic View

Orthographic views are crucial to EDs – they are fundamental in detailing the mechanical and geometric properties of a component. An orthographic view or projection represents a 3D object in 2 dimensions. This 2D view conveys any necessary detail for a part to be produced. This avoids any distortion of lengths, as seen on other views. To communicate all necessary data, three common views are used in multi-view drawings:- Front view

- Top view

- Side view

Flat Pattern View

A flat pattern view is used to represent a bending pattern for a folded sheet metal part. It represents the geometry when bent after being cut from the sheet metal.Section View

A section view is used to display part features that are not evident in standard views. Cross-section views are preferred over hidden lines (as mentioned earlier), as they bring more clarity. Cross hatching is used to represent solid material for cross-section views.Cut-out View

A cut-out view features cross-sectional views on a normal orthographic view, for example, to show a tapped segment without the need for a full section view. It is used to reduce the number of views required on a specific drawing.Detailed View

A detailed view gives a close-up of a selected section to show in more detail. They are useful to show dimensioning in a small area, which is part of a much larger sketch.Auxiliary View

An auxiliary view is an orthographic view that represents planes that are not horizontal or vertical. It shows inclined surfaces without distortion.Dimensions

An ED shows all necessary dimensions for producing a part. Not every measurement of every line is required – this is over dimensioning and means the manufacturer cannot guarantee that all dimensions are 100% correct. Crucial details for dimensions are geometric dimensions and tolerances (GD&T). The limits and fits are important in guaranteeing a longer life with less maintenance. Lower and upper limits or fit classes are essential in a mechanical or manufacturing drawing.Information Blocks

Another key aspect of an ED is information blocks; they contain necessary detail about the part’s assembly. They are often in the bottom right-hand corner of the drawing/part. They provide detail about what the drawing is for, who it’s for, the part number and short description, and detail on the material and finish.Title-Block

The title-block serves as the background in which the drawing should be interpreted. It contains:- The name and address of the company who produced/ owns the drawings

- The part number and description

- Mass

- Material

- General tolerances

- Units

- Finish

- Projection details

- Scale

- Revision number

- Status of the drawing

Assembly Drawings

To avoid all the various minute detail of individual parts on an assembly drawing (which can make them complicated to read) – assembly drawings can be used in conjunction with part drawings. An assembly drawing should clearly detail where each part goes and how it is attached. Exploded views, section views, cut-outs, detailed views, numbered parts, and general dimensions are used to detail the assembly of a product or system.FAQ

Here are some frequently asked questions when reading engineering drawing symbols.

What are the 4 basic components to dimensioning?

- Dimension text

- Dimension lines and arrows

- Extension Lines

- Gaps

These are uniform across the drawing to prevent confusion. Units for the dimensions are found in the title block.

Which font is used?

To avoid mistakes and to make it easy to read, Gothic Sans Serif Script is used. A series of short strokes form this font.

How do I read scale drawings?

Often scales are used to detail a large item on a smaller scale or show the smaller item’s detail on a larger scale.

- When scaling down, i.e., 1:10, the drawing is ten times smaller than in real life.

- When scaling up, i.e., 10:1, the drawing is ten times bigger than in real life.

What are engineering drawings?

Engineering drawings are a specific, detailed outline that depicts all the information required to understand a system or process and the relationship between components.

It’s a graphical language made up of symbols, abbreviations, and measurements to communicate ideas and data.

To see how to markup a P&ID with valve symbols in real-time, follow this video tutorial by Scott Mussbacher, the Systems Integration Lead at Vista Projects.

What are engineering drawings used for?

In general, EDs are used in various civil and mechanical engineering applications – including the detailing, dimensioning, and tolerancing components of a design.

In piping and instrumentation diagrams (P&ID), an ED shows the relationship between piping, process equipment, instrumentation, and control devices to describe an overall process.

A P&ID can make up part of a process flow diagram (PFD), which indicates a more general flow of a plant process and the relationship between major equipment of a plant facility.

Individual components in a P&ID or PFD may have their own engineering drawing to provide additional detail for individual parts, for example, during the installation of a specific component.