The energy sector will rapidly evolve over the next few years, reflecting ongoing innovation, private capital market investment, and the critical need to address global climate change.

Demand for clean energy is expected to skyrocket as energy sector leaders in Canada and the U.S. work toward climate targets of cutting emissions up to 40-50% by 2030, with the hope of establishing an emissions-free power sector by 2035, and achieving net zero emissions economy-wide by 2050.

The importance of quality supply chain management in energy facility construction in North America cannot be overstated. Efficient supply chain management ensures that energy facilities are constructed on time, within the set budget, and meet the highest quality standards.

Role of Supply Chain Management in Energy Facilities Construction

When we refer to energy facility construction, we are talking about the planning, design, and physical implementation, as well as infrastructure specially dedicated to producing, extracting, and generating energy.

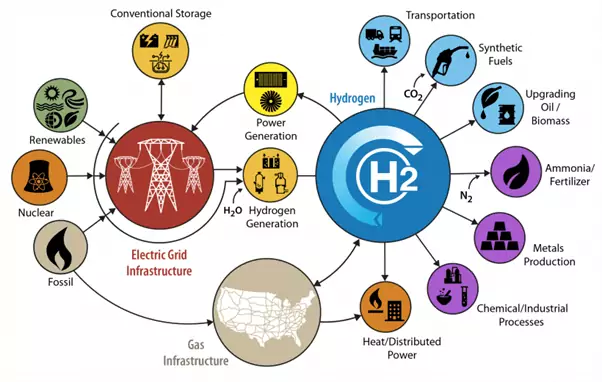

These facilities include a wide range of technologies and sources of renewable energy, hydrogen and nuclear power. Some examples include power plants (coal, natural gas, nuclear, solar, wind, and hydroelectric), refineries, and oil and gas extraction facilities.

The construction of energy facilities goes through numerous stages, from site selection and design to the actual building and commissioning of the facility.

Given how complex and sensitive energy production can be, it requires specialized knowledge and expertise in engineering, environmental concerns, and regulatory compliance.

The Importance of Supply Chain Management in Energy Facilities Construction

The construction of energy facilities is essential for the energy sector, as it directly affects the amount and efficiency of energy generation and the overall energy infrastructure of a region or a country.

But the supply chain is what helps energy facilities get up and running. Let’s explore how:

1. Timely Completion of Projects

One of the main goals is to finish projects on time. Supply chain management helps by making sure materials and equipment arrive when needed. This coordination with suppliers and others prevents delays during construction.

2. Controlling Associated Construction Costs

Controlling costs is also a big focus. Good supply chain management helps save money by improving how materials are bought, negotiating good deals with suppliers, and avoiding unnecessary waste.

3. Quality Assurance of Construction Materials

Maintaining high quality is a must in energy facility construction. Supply chain management ensures that all materials and components meet the required standards through thorough inspections.

4. Manage Associated Risks

Managing risks is essential when working with the construction of energy facilities. Supply chain management helps identify and deal with potential issues like supply chain disruptions or unexpected market changes.

5. Seamless Collaboration

Collaboration among everyone involved, from subcontractors to suppliers, is made more accessible through supply chain management. This teamwork ensures that everyone is working toward the same project goals.

Improving Supply Chain Management for Energy Facility Construction

Here’s how to improve supply chain management for energy facility construction:

1. Encourage Collaboration Among Teams

Avoid making the mistake of placing all supply chain responsibilities on one person, often only one procurement officer. Instead, form a highly-skilled procurement team and promote collaboration as a critical part of efficient supply chains.

To increase teamwork, you should also ensure communication is clear among everyone involved, from project managers to external partners.

2. Use the Just-in-Time Inventory System to Avoid Stockups and Delays

Streamline the construction process by focusing on just-in-time delivery. This means getting materials on-site exactly when needed, reducing excess inventory and waste.

Try finding logistics partners to work with who offer flexibility in ordering and allow adjustments based on project changes.

3. Set Clear Targets for Everyone Involved

Ensure quality by setting clear goals for each step in the supply chain. You should also regularly review the quality of construction materials, costs, and timeliness.

Aside from that, establish and track key performance indicators (KPIs) for all partners, creating a list of preferred suppliers and dealers over time.

4. Use Digital Tools for Construction Management:

Update how construction is managed using digital tools designed for the energy facility construction industry. These tools centralize essential data, providing easy access for everyone.

Connect these tools with online marketplaces used by material suppliers for smoother procurement processes.

5. Document and Share the Supply Chain Plan

Clearly outline the supply chain management plan for energy facility construction. You should also document the plan, regularly review it, and share it with everyone in the supply chain. This prevents confusion and keeps everyone on the same page.

Challenges Faced By the Energy Facilities Construction Industry

Two significant challenges contributed to the industry’s transformation and the restructuring of supply chains.

Firstly, the industry is grappling with a persistent shortage of critical building materials. The impact of COVID-19, coupled with widespread lockdowns and production disruptions, has led to unprecedented delays in sectors traditionally accustomed to producing based on forecasts and in an anticipated manner — such as metal products, parts, and lumber.

These industries and their supply chains are known for being slow to adapt to abrupt changes, and they are still working to catch up on the backlog of production volumes. Consequently, construction, like many other sectors, faces supply chain hurdles linked to the production and timely delivery of these materials for projects.

Numerous commodity materials have seen significant price increases. This not only boosts the ultimate project cost but also jeopardizes the supply chain’s ability to fulfill the planned on-time delivery date, often assumed when funding is secured.

This difficulty is fundamental in energy facility building when obtaining timely materials is critical to project success.

Conclusion

Efficient supply chain management is vital for constructing energy facilities in North America amid the evolving energy sector. It ensures projects finish on time, controls costs, and maintains quality.

Challenges like material shortages require solutions such as collaboration and just-in-time inventory systems. Optimized supply chain management is crucial for achieving climate targets and building a resilient energy infrastructure.

Looking for a construction partner for your energy project?

Vista Projects – an integrated engineering services firm – and top-ranked employer – is able to assist with your energy facility construction projects. With offices in Calgary, Alberta, Houston, Texas, and Muscat, Oman, we help clients tailor engineering phases for the unique needs of their projects. Contact us today!

Looking for purpose-built procurement software for your energy project?

Current SCM is the first of its kind – supply chain management software purpose-built to support the most complex procurement & materials management projects. With Materials Management and Vendor Document Requirements uniquely integrated into the Order, Current SCM provides a unified, collaborative platform to streamline the end-to-end process of project-driven procurement & materials management.

Looking for your next (last?) great job at an EPC firm?

Vista Projects is hiring for multiple roles in engineering and system integration – apply today!