Many global energy markets have been placed in turmoil due to sanctions and disruption to supply chains. Canada may be poised to play a key role in filling the gap between demand and supply in the months and years to come. This could create a massive opportunity for the Canadian oil and gas sector, but many significant challenges must be faced.

Challenge #1 – How to increase production to meet new market demands

Much of Canada’s oil sector is scrambling to increase production.

Sanctions on Russian oil and gas are creating a global increase in demand for energy. This is especially the case in Europe, which is reliant on Russian gas and has insufficient resources to meet its own needs.

With plans for increased U.S. exports to Europe, Canada has an opportunity to fill the gap in demand. Recognizing this opportunity, Canada’s Natural Resources Minister Jonathan Wilkinson recently announced increases in production of the order of 300,000 barrels per day.

Increasing production from oil sands using technologies such as steam-assisted gravity drainage (SAG-D) could play a major role in quickly maximizing output. SAG-D is one of the methods used to extract bitumen from underground oil sands deposits.

“We are expecting some growth from Canada, but for a meaningful difference, it’s tough because you need big oilsands expansion projects,” says Phil Skolnick, Canadian oil analyst with New York-based Eight Capital.

There is already approval for more than 2.5 million barrels per day of new production capacity. The challenge will be to secure the financing, materials, resources, and expertise quickly to take advantage of the situation.

Typical SAG-D facilities take 2-3 years from initiation to production, while new oil sand mines take up to 5 years. SAG-D projects have a marked advantage due to their “speed to market” and the trusted technologies used. But securing materials and resources in the current climate of disrupted trade and soaring prices will be a challenge.

Projects to increase production in existing SAG-D operations would benefit the industry. De-bottlenecking opportunities such the ones listed here contributing to up 15,000 Barrels-per-day (BDP) in expanded supply from previously maximum capacity facilities. Efficiencies can be realized using targeted investments to modify existing facilities.

Challenge #2 – Increase efficiency and reduce water/energy usage

The efficiency and effectiveness of SAG-D has increased dramatically over the last few years. Advances in processes and technologies have vastly improved the inputs required for production.

But the industry is striving to go further to develop solutions which will:

- Reduce the amount of water used, and maximize water recovery

- Reduce the amount of energy to create steam and reduce heat loss

- Reduce the overall carbon footprint of the sector

Significant advances are underway.

Expanding Solvent Assisted Gravity Drainage (ESAG-D) is the injection of aromatic solvents with steam. This method has been effective in reducing the amount of water (through replacement with solvents) and increases the viscosity of the oil. This results in less water/solvent volumes used, which reduces energy consumption in the overall process.

Rich Solvent Assisted Gravity Drainage (RSAG-D) aims to further reduce the level of steam required using alternative solvents and mixtures. Reductions in water consumption of up to 60% have been noted.

Enhanced water recovery systems have targeted reductions in the amount of fresh water being used within SAG-D (with and without solvents).

The steam to oil ratio describes a facility’s ability to use water effectively to produce oil. Through challenging previous assumptions, new innovations are in operation to improve performance. The ability to safely return “used” water to be reused for steam without re-boiling has resulted in steam-to-oil ratios of 2:1 reached on modern facilities.

Challenge #3 – Transition to manufacturing and new technologies

The recent global energy crisis has highlighted the need for dependable energy sources as back-ups in the global system. There have also been conversations about alternative uses of bitumen to expand low-carbon opportunities as well.

The research into possible uses of bitumen in new technologies and products is an example of using existing raw materials in innovative ways.

“Alberta’s vast reserves of bitumen are the building blocks to create new low-carbon opportunities throughout the province” says Alberta Innovates CEO Laura Kilcrease. The company is working with the University of Calgary to create novel ways of producing:

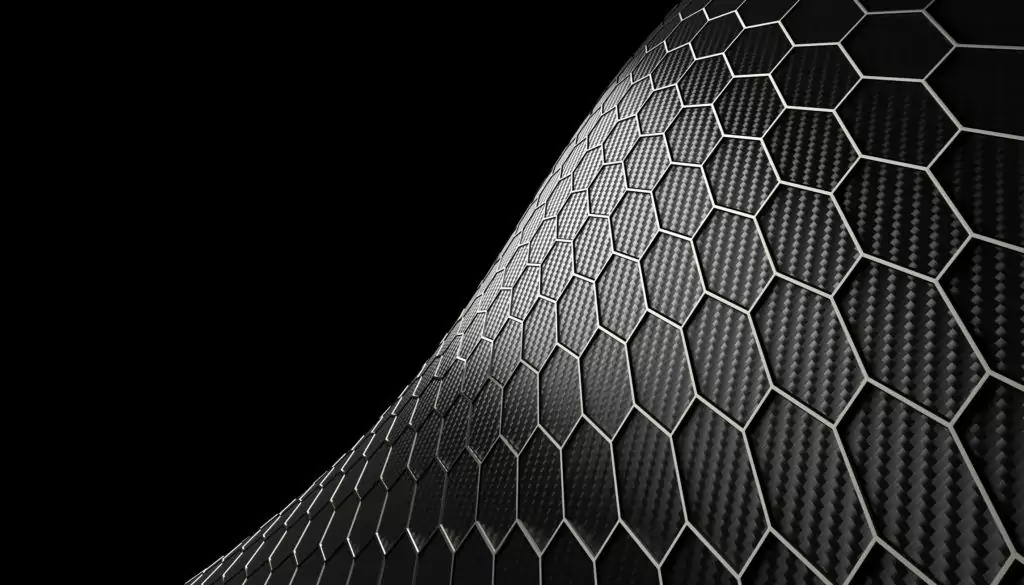

- Carbon fibers

- Graphene

- Polyurethanes

- Fertilizers

- And high-quality asphalts

One telling example of this transformation of the industry from carbon producing to carbon neutral is the manufacture of carbon fiber. Carbon fibers from bitumen can be manufactured into carbon fiber reinforced materials, ultimately engineered for use in the aerospace industry.

The use of light-weight carbon fiber reinforced plastics reduces the weight of the aircraft which in turn requires less energy to travel. Modern aircraft manufacturers are re-designing more and more of their aircraft structures, interiors and skins using ultra-light weight carbon fiber materials to take advantage of their low weight to stiffness ratio.

The use of carbon fiber materials can greatly reduce the energy consumption within the airline industry, reducing the carbon footprint for the sector.

Conclusion

The oil and gas industry in Canada faces significant opportunities and challenges in the near future. The current energy crisis may provide a medium-term benefit and challenge to current producers. The difficulty of increasing output through new projects and technologies will strain the existing global supply chains. Novel solutions to expand capacity and pivot into new industries are possible as listed in the examples above.

The long-term re-organization of the sector remains a key challenge but with promising innovations on the horizon, the future is bright for the industry.

Planning a SAG-D project?

Vista Projects is an integrated engineeringThe process of integrated engineering involves multiple engineering disciplines working in conjunction with other project disciplines to e... services firm able to assist with your SAG-D projects. With offices in Calgary, Alberta, and Houston, Texas, we help clients with customized system integration and engineering consulting across all core disciplines.