Mechanical engineering is a core branch of professional engineering. It focuses on the conception, design, manufacture, maintenance, and evaluation of mechanical and thermal systems using physical and mathematical concepts.

Mechanical engineering works in unison with other engineering fields such as civil, chemical, electrical, and electronics. Multidisciplinary engineering plays an important role in today’s industrial world.

This article covers the following topics:

- Mechanical Engineering – Overview and Applications

- Subdisciplines of Mechanical Engineering

Overview and Applications

Mechanical engineering mainly works on mechanisms and fluids. Mechanisms transmit force using solid components such as links, joints, and other machine elements. Force, energy, and motion are the key interests in studying mechanisms and structural analysis.

Mechanisms are useful in everyday life as they allow for the efficient use of force to simplify work. Fluids are used as media for transferring energy and power, usually in the form of heat or thermal energy.

Fluids can be manipulated through compression, expansion, heating, or cooling. These processes make them behave in a certain way with their surroundings. Examples include absorbing or exerting energy or producing motion and work.

Mechanical engineers collaborate with other engineering disciplines, such as chemical, civil, electrical, and piping. Multidisciplinary engineering teams work together to complete systems and processes. The following are some of the industrial applications of mechanical engineering.

- Oil and Gas

- Petrochemicals

- Gas Separation

- Utility Systems

- Thermal Power Plants

- Renewable Energy

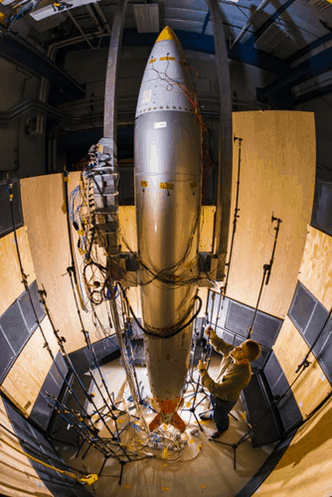

- Aerospace

- Automotive

- Manufacturing

- Construction

- Robotics and Mechatronics

- Material Handling

- Nanotechnology

- Biomechanics

Subdisciplines of Mechanical Engineering

Mechanical engineering is regarded as one of the most diverse engineering disciplines. Some of its concepts overlap with other engineering crafts. However, there are key subjects that separate it from the rest. Summarized below are some sub-disciplines commonly studied under mechanical engineering programs.

Thermodynamics

Thermodynamics is the study of energy. It mainly deals with thermal energy and how it is converted into thermodynamic work.

Thermodynamics in mechanical engineering is different from that of chemical engineering. Chemical engineering, also known as process engineering, focuses on the different forms of energy and its conversion through chemical processes.

Mechanical engineering thermodynamics is the study of energy at a macroscale. This helps define relationships between pressure, temperature, volume, enthalpy, and entropy. It is governed by laws of energy conservation and gas laws.

Thermodynamics further branches into other sub-disciplines such as refrigeration, power generation, and internal combustion engines.

Fluid Mechanics

This is the study of forces and energy on liquids and gases, which are regarded as deformable bodies. Fluid mechanics can be divided into two categories: fluid statics and fluid dynamics.

Fluid statics, the simpler of the two, involves fluids at rest. Fluid dynamics aims to predict or describe the behavior of liquids and gases in motion.

Fluid dynamics is used in applications such as hydropower, fluid machinery, lubrication, and aeronautics.

Fluid Mechanics

Heat or thermal engineering studies the movement and transfer of heat energy. The physical concepts tackled in this subdiscipline represent the three modes of heat transfer:

- Conduction

- Convection

- Radiation

Heat transfer includes the thermal properties of materials. Examples include specific heat, thermal conductivity, coefficient of thermal expansion, melting point, and boiling point.

Heat transfer is applied to the design of thermal insulations of buildings and equipment, heat exchangers, pipes, heaters, and refrigeration units.

Fuels and Combustion

This is the study of converting chemical energy in the form of organic fuels into thermal energy. Examples include coal, gasoline, diesel, and natural gas.

Fuels and combustion engineering analyzes fuels by determining their composition, the amount of energy contained, and the efficiency of combustion. This subject is useful in applications such as internal combustion engines, power plants, or aerospace engineering, and petroleum refining.

Power Plant Engineering

This is an interdisciplinary field that makes use of both mechanical and electrical engineering.

The mechanical engineering side is concerned with the processes for creating power. Power is generated through the combination or sequence of thermodynamic processes known as power cycles.

Power cycles convert heat energy from fuels such as coal, biofuel, natural gas, and geothermal heat into usable mechanical energy. Commonly known cycles are Rankine, Brayton, Stirling, and Ericsson.

Among the power cycles, Rankine and Brayton’s cycles are extensively used. They are typically seen in steam, gas, and combined cycle power plants.

Internal Combustion Engine (ICE)

This is the design and analysis of internal combustion engines. ICE is used in automotive vehicles, ships, trains, airplanes, and even power generation plants.

Like power plant engineering, ICE deals with thermodynamic power cycles. The most widely studied cycles are the Otto and Diesel cycles. ICE aims to improve the performance, fuel efficiency, and environmental impact of engines.

Refrigeration

Refrigeration is the study of thermodynamic heat pump cycles. It involves a working fluid, called a refrigerant, for transferring heat from one space to another.

This transfer of heat can be the opposite of the natural flow of energy. With refrigeration, heat can be further extracted from a region with lower temperatures in exchange for mechanical energy. This makes it possible to cool spaces below ambient or even at sub-zero temperatures.

Applications of refrigeration are cold storage, space cooling, air conditioning, and gas production.

Heating, Ventilation, and Air Conditioning (HVAC)

Refrigeration is the study of thermodynamic heat pump cycles. It involves a working fluid, called a refrigerant, for transferring heat from one space to another. This transfer of heat can be the opposite of the natural flow of energy. With refrigeration, heat can be further extracted from a region with lower temperatures in exchange for mechanical energy. This makes it possible to cool spaces below ambient or even at sub-zero temperatures. Applications of refrigeration are cold storage, space cooling, air conditioning, and gas production.

Machine Design

Machine design is one of the two main subdisciplines of mechanical engineering. The other is thermo-fluids. Great for problem solving, machine design aims to conceptualize, build, and analyze a mechanical element or system.

It is important that mechanical engineers design solutions to achieve sufficient strength, intended functionality, reliability, safety, and economical production. Computer-aided design (CAD) software programs are very common in this field.

This subject encompasses other areas such as mechanics, the strength of materials, machine elements, fabrication, and manufacturing.

Mechanics of Rigid Bodies

Mechanics of rigid bodies is the study of motion, forces, and energy and their effects on solid bodies. This study is mostly governed by Newton’s laws of motion.

Mechanics is a fundamental concept for real-world applications. Such applications are mechanical and civil structures, robotic actuator systems, automotive, and aerospace.

This subject can be divided into three general topics: statics, dynamics, and kinematics.

- Statics deals with non-moving bodies affected by forces in equilibrium.

- Dynamics centers on analyzing matter subjected to an initial force or acceleration caused by the unbalance of forces.

- Kinematics analyzes the motion of bodies or whole mechanical systems without considering the forces that cause the motion.

Strength of Materials

This is the study of the effects of different types of stresses on solid objects and their behavior under such conditions. The strength of materials predicts the response of materials, particularly deflection, and the most possible mode of failure.

This subject is required in designing structural members such as beams, shafts, columns, plates, and slabs.

Machine Elements

Machine elements is the subject that tackles the basic parts of a mechanical system. Examples of machine elements are belt drives, chain drives, gears, linkages, joints, frame members, bearings, and springs.

Breaking down a mechanical system into its elementary components simplifies the design and selection process. This comprehensive process helps to ensure each machine element specifically meets the design criteria.

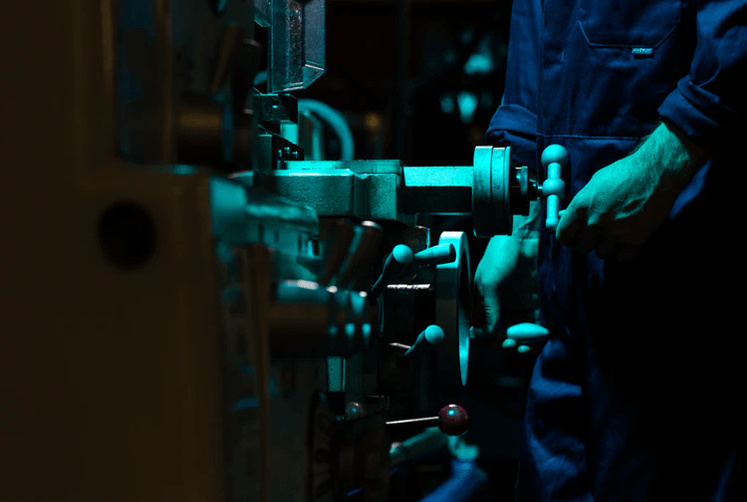

Fabrication and Manufacturing Engineering

This subdiscipline concentrates on the production of a complete mechanical system. Fabrication is the generation of structures with defined geometries and properties from different engineering materials.

Manufacturing is the design of processes and technologies to optimize production in terms of cost, efficiency, and quality.

What is Mechanical Engineering & Why Does it Matter?

Mechanical engineering is a critical field for solving complex problems and creating innovative solutions.

There are many degrees in mechanical engineering, especially in the United States, home to the American Society of Mechanical Engineers. ASME is a professional association that “promotes the art, science, and practice of multidisciplinary engineering and allied sciences.”

Mechanical engineers study and apply concepts of energy and motion. Their work creates better devices and machines that are useful in everyday life.

Multi-Discipline Engineering Services

Vista Projects is an integrated engineering services firm able to assist with your mechanical engineering requirements. With offices in Calgary, Alberta, and Houston, Texas, we help clients with customized system integration and engineering consulting across all core disciplines.

Civil Structural

Electrical

Instrumentation & Controls

Mechanical

Piping

Process